Description

Victron Venus GX

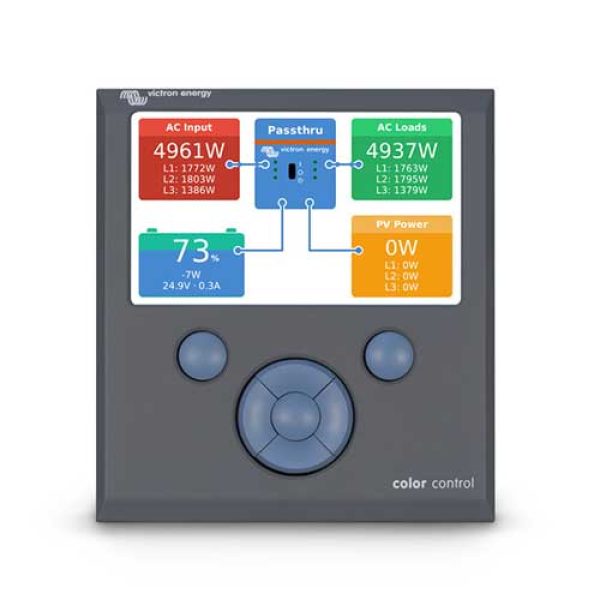

The Victron Venus GX is a gateway device that provides intuitive control and monitoring for all Victron power systems. It can be used to monitor and control a wide range of Victron components, including inverters, chargers, solar panels, batteries, and more. The Victron Venus Gx also has a number of built-in features that make it a valuable tool for managing your off-grid or backup power system, including:

- Real-time monitoring: The Venus GX can display the current status of your entire power system in real time, including the voltage, current, and power of all connected components.

- Remote monitoring: The Venus GX can be monitored and controlled remotely using the VictronConnect app or the Victron Remote Management (VRM) portal. This means you can check on the status of your power system from anywhere in the world.

- Automatic load shedding: The Victron Venus Gx can be configured to automatically shed loads if the power system reaches a critical level. This helps to prevent damage to your components and ensures that your critical loads are always powered.

- Automatic generator start: The Victron Venus Gx can be configured to automatically start your generator if the battery voltage drops below a certain level. This ensures that your power system never runs out of power.

- Data logging: The Victron Venus Gx can log data from all connected components for up to 1 year. This data can be used to troubleshoot problems, optimize your power system, and track your energy usage.

Compatible products :

- Multi and Quattro, including three-phase and split-phase systems. Monitoring and control (On / Off and current limiter). It is possible to change the configuration (only remotely through the Internet, impossible without an Internet connection).

- BlueSolar MPPT solar chargers with VE.Direct port.

- BlueSolar MPPT 150/70 and MPPT 150/85 with a VE.Can port. When many BlueSolar MPPTs with VE.Can are used in parallel, all information is grouped into one. See also our blog post about syncing multiple MPPT 150/70 solar chargers.

- The BMV-700 family can be connected directly to the VE.Direct ports on the Victron Venus Gx. To do this, use the VE.Direct cable.

- The BMV-600 family can be connected directly to the VE.Direct ports on the Victron Venus Gx. Auxiliary cable needed

- Lynx Ion Shunt

- BMS Lynx Ion

- Lynx Shunt VE.Can

- Skylla-i battery chargers

- NMEA2000 tank probes

- A USB GPS can be connected to the USB port. The data is sent to the VRM Portal for localization purposes.

- The map on the VRM will show the last position.

- Fronius PV Converters

If more than two VE-Direct products need to be connected, a USB cable can be used.

Victron Venus GX VRM Online Portal

All readings are transmitted by the Victron Venus GX to our free remote monitoring website: the VRM Online Portal. To get an idea, try the demo at https://vrm.victronenergy.com. With the remote console, you can access the device to configure it and also to monitor it. Whether via the VRM, the built-in Wi-Fi hotspot, or through the LAN / WiFi LAN.

| Venus GX | |

| Supply voltage range | 8 – 70 VCC |

| Current draw | 210 mA @ 12V 110 mA @ 24V 60 mA @ 48V |

| Communication ports | |

| VE.Direct | 2 separate VE.Direct ports – isolated |

| VE.Can | 2 RJ45 connectors in parallel – isolated |

| CAN | 2nd CAN Interface – not isolated |

| VE.Bus | 2 RJ45 connectors in parallel – isolated |

| USB | 2 USB Host ports – uninsulated |

| Ethernet | RJ45 10/100/1000 MB RJ45 connector – isolated except shielding |

| Point d’accès Wi-Fi | To connect to the Remote Console |

| Wi-Fi Client | To connect to the Remote Console |

| IO | |

| Dry contact | NO/COM/NC – 6 A 250 VCA / 30 VCC |

| Connections for fuel level | 3 x configurable for Europe (0 – 180 Ohm) or US (240 – 30 Ohm) |

| Connections for temperature | 2 x ASS000001000 required |

| Third party interfaces | |

| Modbus-TCP | Use the Modbus-TCP protocol to monitor and control all products connected to the Venus GX |

| JSON | Use the VRM JSON API to extract data from the VRM Portal |

| Others | |

| External dimensions (h x w x d) | 45 x 143 x 96 |

| Operating temperature range | -20 to 50°C |

| Standards | |

| Security | EN 60950 |

| EMC | EN 61000-6-3, EN 55014-1, EN 61000-6-2, EN 61000-6-1, EN 55014-2 |

| Automotive | In progress |

Reviews

There are no reviews yet.